What are underwater emissaries?

The underwater pipelines intended to move sewage, the conduction of salt water and to capture seawater are given this name.

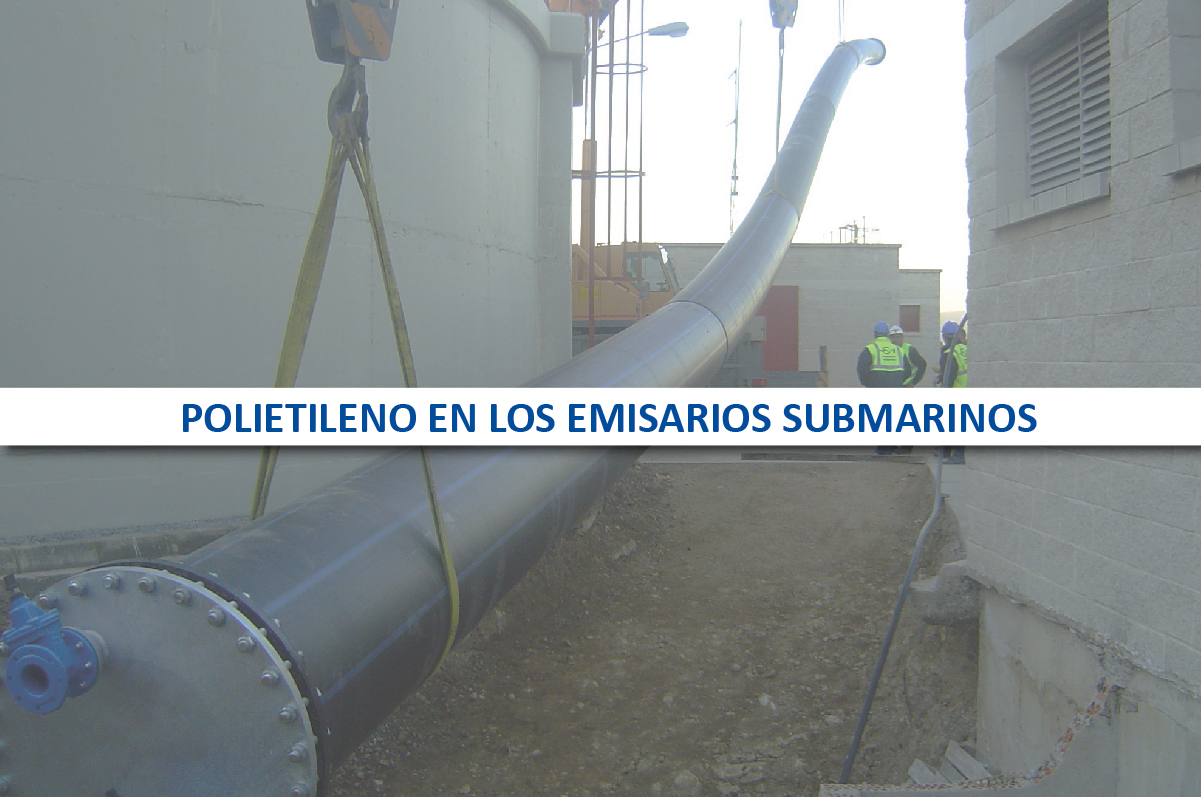

Underwater emissaries are flexible, pressure-operated tubes that have a wide diameter at the same time as a lot of length. These characteristics allow them to transport sewage inside to the bottom of the sea.

So that underwater emissaries can do all their functions are usually made of polyethylene (PE), as it is the most suitable plastic for this procedure.

What is the role of underwater emissaries?

Mainly underwater emissaries are used to disinfect wastewater by seawater and seabed qualities. Wastewater is purified through the chemical, physical and biological process that causes seawater’s salinity, temperature and ultraviolet radiation. This process will help reduce environmental damage.

Another of its uses and also very important is the case of coastal dry areas, the desalination plants take the water from inland through underwater emissaries,therefore they are essential.

What advantages does the EP bring in the construction of undersea emissaries?

- The supply of polyethylene pipes is fast thanks to its length of 13 to 15 meters in length and its lightness compared to other materials, such as steel.

- PE is a very flexible material and very suitable for deformation.

- Polyethylene is a very resistant material. This material will ensure that no breakages or leaks due to strong waves,to sea currents or the instability of these a bed.

- It is necessary to highlight its resistance to marine corrosion.

- The PE allows to install long sections of pipe on the ground.

- No excessive joints will be required for pipes. These joints will be made with thermofusion welding on the same seashore and then transport the stretches floating to the desired place where they will proceed to sink them conditions that introduces into the towing and anchoring maneuvers are less than in others Materials.

- The costs of building underwater polyethylene emissaries are not very high thanks to the possibility of building long sections on land and avoiding many joints under the sea.